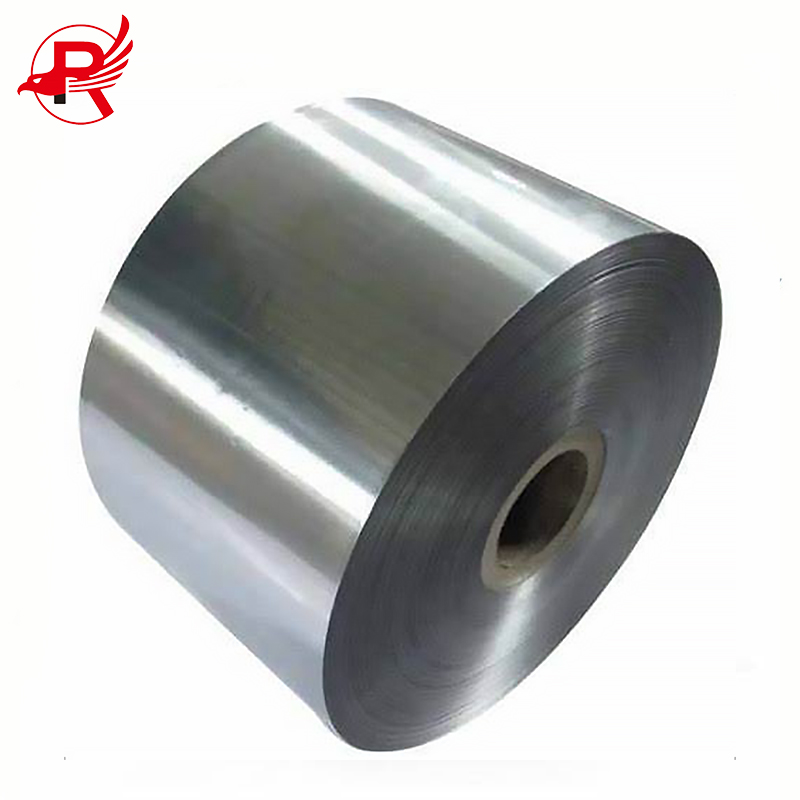

6061 Zavojnica od aluminijske legure za gradnju zgrada

| 1) Legura serije 1000 (općenito se naziva komercijalni čisti aluminij, Al>99,0%) | |

| Čistoća | 1050 1050A 1060 1070 1100 |

| Temperament | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/ H26/H36 H18/H28/H38 H114/H194, itd. |

| Specifikacija | Debljina ≤ 30 mm; Širina ≤ 2600 mm; Duljina ≤ 16000 mm ILI zavojnica (C) |

| Primjena | Poklopci, industrijski uređaji, skladištenje, sve vrste spremnika itd. |

| Značajka | Poklopac Visoka vodljivost, dobra otpornost na koroziju, visoka latentna toplina taljenja, visoke refleksije, dobrog svojstva zavarivanja, niske čvrstoće i ne pogodno za toplinske obrade. |

| 2) Legura serije 3000 (općenito nazvana legura Al-Mn, Mn se koristi kao glavni element legure) | |

| Legura | 3003 3004 3005 3102 3105 |

| Temperament | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/ H36 H18/H28/H38 H114/H194, itd. |

| Specifikacija | Debljina ≤ 30 mm; Širina ≤ 2200 mm Duljina ≤ 12000 mm ILI zavojnica (C) |

| Primjena | Dekoracija, uređaj za odvod topline, vanjski zidovi, skladištenje, ploče za gradnju itd. |

| Značajka | Dobra otpornost na hrđu, nije prikladno za toplinsku obradu, dobra otpornost na koroziju performanse, dobra svojstva zavarivanja, dobra plastičnost, niska čvrstoća, ali prikladno za hladno kaljenje |

| 3) Legura serije 5000 (općenito nazvana legura Al-Mg, Mg se koristi kao glavni element legure) | |

| Legura | 5005 5052 5083 5086 5182 5754 5154 5454 5A05 5A06 |

| Temperament | O/H111 H112 H116/H321 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, itd. |

| Specifikacija | Debljina ≤ 170 mm; Širina ≤ 2200 mm; Duljina ≤ 12000 mm |

| Primjena | Ploča za brodove, Završni dio limenke s prstenastim izvlačenjem, Završni dio s prstenastim izvlačenjem, Automobilski Limovi za karoseriju, unutarnja ploča automobila, zaštitni poklopac na motoru. |

| Značajka | Sve prednosti normalne aluminijske legure, visoka vlačna čvrstoća i granica razvlačenja, dobra otpornost na koroziju, dobra svojstva zavarivanja, dobra čvrstoća na umor, i pogodan za anodnu oksidaciju. |

| 4) Legura serije 6000 (općenito nazvana legura Al-Mg-Si, Mg i Si se koriste kao glavni elementi legure) | |

| Legura | 6061 6063 6082 |

| Temperament | OD, itd. |

| Specifikacija | Debljina ≤ 170 mm; Širina ≤ 2200 mm; Duljina ≤ 12000 mm |

| Primjena | Automobilska industrija, Aluminij za zrakoplovstvo, Industrijski kalupi, Mehaničke komponente, Transportni brod, poluvodička oprema itd. |

| Značajka | Dobra otpornost na koroziju, dobra svojstva zavarivanja, dobra oksidabilnost, lako se nanosi prskanjem, dobro se oksidira i dobro se obrađuje. |

Kao višenamjenski materijal, aluminijske zavojnice imaju širok raspon upotrebe u raznim područjima.

Prije svega, u području građevinarstva, aluminijske zavojnice se često koriste u uređenju vanjskih zidova zgrada, krovova, stropova, okvira prozora itd. Budući da aluminijske zavojnice imaju dobru otpornost na vremenske uvjete i dekorativna svojstva, mogu zadovoljiti zahtjeve izgleda i trajnosti zgrada.

Drugo, u području prijevoza, aluminijske zavojnice često se koriste za izradu školjki, karoserija, unutarnjih dijelova itd. vozila poput automobila, vlakova i aviona. Lagana priroda aluminijskih zavojnica pomaže u smanjenju ukupne težine vozila i poboljšanju učinkovitosti goriva.

Osim toga, u području elektroničkih i električnih uređaja, aluminijske zavojnice se često koriste za izradu kućišta baterija, radijatora, kućišta elektroničkih proizvoda itd. Svojstva električne vodljivosti i odvođenja topline aluminijskih zavojnica čine ih važnim materijalom u elektroničkoj i električnoj industriji.

Osim toga, u području pakiranja, aluminijske zavojnice se također široko koriste u pakiranju hrane, farmaceutskoj ambalaži itd. Budući da aluminijske zavojnice imaju dobro brtvljenje i otpornost na oksidaciju, mogu učinkovito zaštititi kvalitetu i sigurnost pakiranih predmeta.

Općenito, aluminijske zavojnice imaju važnu primjenu u građevinarstvu, transportu, elektroničkim uređajima, pakiranju i drugim područjima. Njegova mala težina, otpornost na koroziju i jednostavna obrada čine ga jednim od nezamjenjivih materijala u raznim industrijama.

| ŠIRINA (MM) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 1000 | 1 | 2 | 3 | 4 | Ostalo |

| 1219 | 1 | 2 | 3 | 4 | Ostalo |

| 1220 | 1 | 2 | 3 | 4 | Ostalo |

| 1500 | 1 | 2 | 3 | 4 | Ostalo |

| 2000. | 1 | 2 | 3 | 4 | Ostalo |

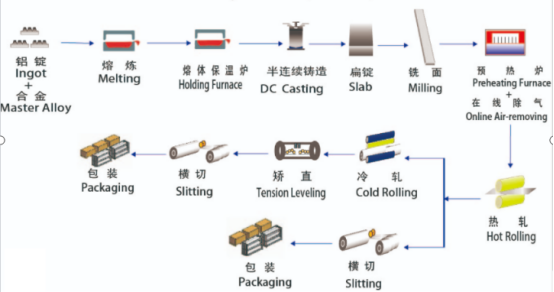

Proizvodnjaaluminijski čelikObično prolazi kroz više koraka. Prvo, počevši od aluminijskih ingota, kroz taljenje i polukontinuirano lijevanje, dobiva se tekući aluminij koji zadovoljava zahtjeve. Zatim se rastaljeni aluminij lijeva u aluminijsku ploču postupkom kontinuiranog lijevanja i valjanja, a zatim se debljina postupno smanjuje pomoću stroja za kontinuirano valjanje kako bi se formirala potrebna aluminijska zavojnica. Nakon toga, aluminijska zavojnica se kali i žari kako bi se prilagodila njezina struktura i svojstva te poboljšala njezina čvrstoća i plastičnost. Konačno, aluminijske zavojnice mogu se premazati kako bi se povećala otpornost na koroziju ili dekorativna svojstva na njihovim površinama. Cijeli proizvodni proces zahtijeva strogu kontrolu kako bi se osiguralo da kvaliteta i performanse proizvoda zadovoljavaju standardne zahtjeve. Istovremeno, zaštita okoliša, potrošnja energije i drugi aspekti također su pitanja na koja se treba usredotočiti tijekom proizvodnog procesa.

Evo nekoliko ključnih čimbenika koje treba uzeti u obzir prilikom pregledaaluminijska zavojnica:

1. Veličina: Provjerite veličinuzavojnica od aluminijske legureu skladu sa specifikacijama proizvođača. Provjerite da su ispravne debljine, širine i duljine.

2. Kvaliteta površine: Provjerite površinu zavojnice na ogrebotine, udubljenja ili druge nedostatke. Površina treba biti glatka bez ikakvih vidljivih oštećenja.

3. Konzistentnost boje: boja zavojnice treba biti konzistentna po cijeloj zavojnici. Svaka promjena boje može ukazivati na problem s proizvodnim procesom.

4. Debljina premaza: Ako zavojnica ima premaz, treba provjeriti debljinu premaza kako bi se osiguralo da ispunjava određene zahtjeve. Premazi koji su previše tanki ili previše debeli mogu utjecati na trajnost i performanse proizvoda.

5. Kemijski sastav: analizirati kemijski sastav aluminija kako bi se osiguralo da ispunjava potrebne standarde. To uključuje provjeru nečistoća ili drugih elemenata koji bi mogli utjecati na kvalitetu proizvoda.

6. Pakiranje i označavanje: Osigurajte da su role pravilno zapakirane i označene za otpremu i skladištenje. Ambalaža treba biti čvrsta i dizajnirana da zaštiti zavojnicu tijekom transporta.

7. Proizvodni proces: Proizvodni proces se pregledava kako bi se osiguralo da ispunjava potrebne standarde te da je sva oprema pravilno održavana i u ispravnom stanju.

Učinkovit proces inspekcije pomoći će u prepoznavanju svih potencijalnih problema s proizvodom i osigurati da on zadovoljava potrebne standarde kvalitete.

Ambalaža je uglavnom gola, čelična žica za uvez, vrlo jaka.

Ako imate posebne zahtjeve, možete koristiti ambalažu otpornu na hrđu i ljepšu.

Prijevoz:Ekspresna dostava (dostava uzorka), zračni, željeznički, kopneni, pomorski prijevoz (FCL ili LCL ili rasuti teret)

P: Jesu li UA proizvođač?

O: Da, mi smo proizvođač. Imamo vlastitu tvornicu koja se nalazi u gradu Tianjinu u Kini. Osim toga, surađujemo s mnogim državnim poduzećima, kao što su BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP itd.

P: Mogu li dobiti probnu narudžbu samo nekoliko tona?

O: Naravno. Možemo vam poslati teret s LCL uslugom (manje kontejnerskog tereta).

P: Ako je uzorak besplatan?

O: Uzorak je besplatan, ali kupac plaća troškove prijevoza.

P: Jeste li dobavljač zlata i nudite li jamstvo trgovine?

O: Sedam godina smo dobavljač zlata i prihvaćamo trgovinsko jamstvo.